Quick draw facts of anchoring to concrete

There are many ways to anchor public structures, and while most are sufficiently secure and robust for all types of conditions, there are advantages and disadvantages.

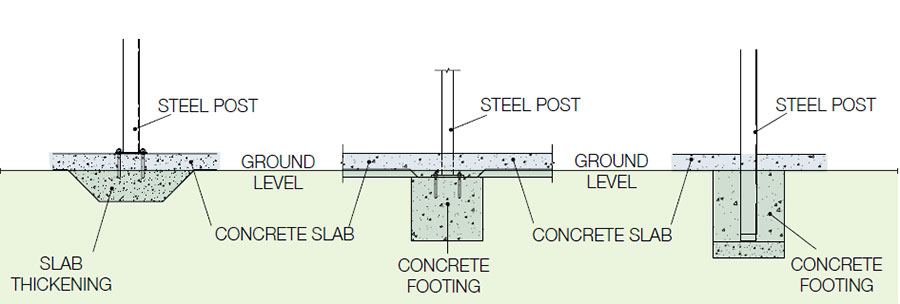

Broadly speaking, methods of anchoring structures to concrete slabs fall into two categories – bolt-down (sometimes known as flange mounted) and inground (core mounted).

As the name suggest, bolt-down involves vertical posts (either steel or timber) of a structure resting on top of a previously poured slab, being fixed by bolts/fastening systems passing through plates or brackets into the concrete.

On the other hand, inground involves pouring concrete around the posts, either firstly securing using a pre-poured footing (followed by the slab), or as part of a complete slab being poured.

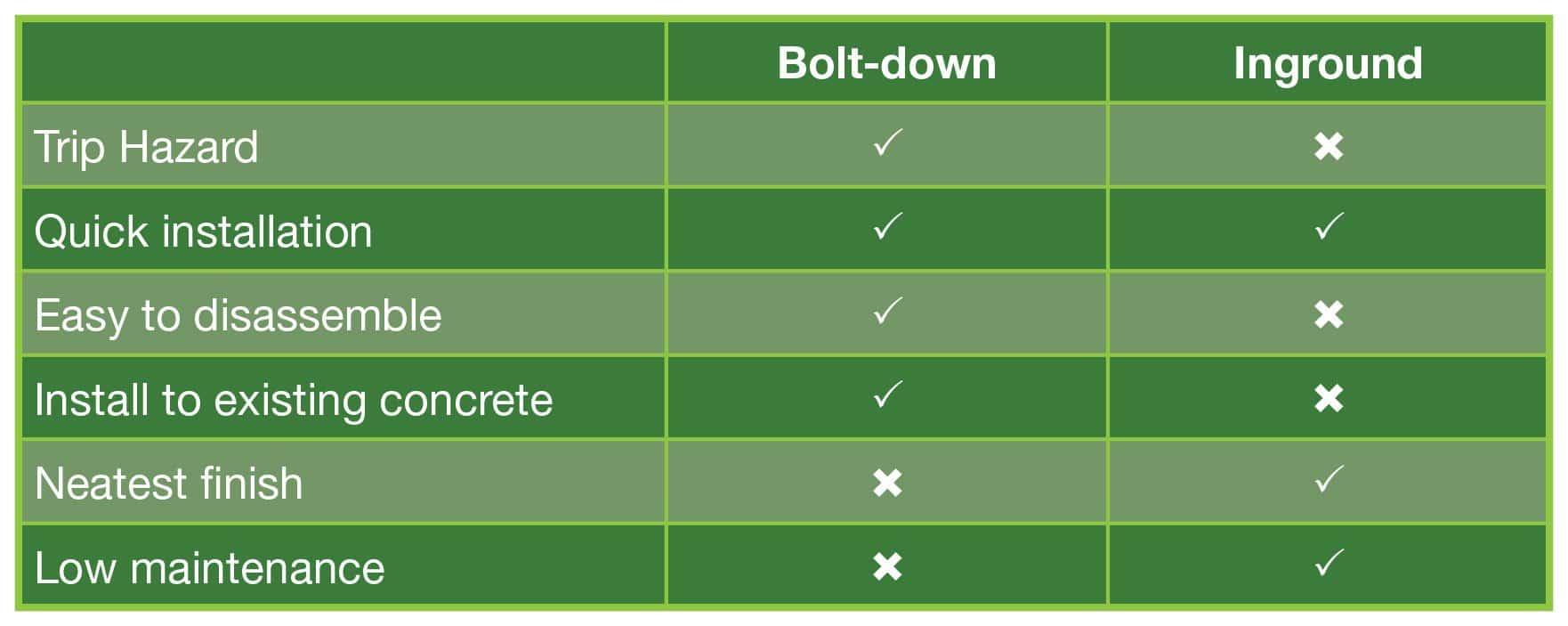

Although there are more benefits to inground anchoring, on many occasions this method is sometimes overlooked because of issues of installation timing.

Inground anchoring is only possible if the structure kit arrives before the slab is poured, and therefore needs to be planned accordingly. Many times, however, this is not possible.

A subset method of inground is “bolt below”, whereby “blinding pads” for each of the vertical posts are first poured to the bottom of the proposed slab, ensuring that each are level. The posts can then be secured by chemical-set posts (or other appropriate anchors) and then the complete slab can be poured.

The other method of “inground” is to simply pour the concrete slab or footing as one entity around the pre-positioned and braced posts/brackets.

It depends on your individual situation, however have the conversation with your Project Consultant when selecting your product to choose the best method of anchoring.

What are the advantages and disadvantaged of each method:

Most Landmark Products can be adapted to either bolt-down and inground, and a highly-skilled installation team experienced in both. For more details, contact your local Landmark Project Consultant.